Auto petroleum Vaseline wax heating filling sealing capping machine line

Process steps:

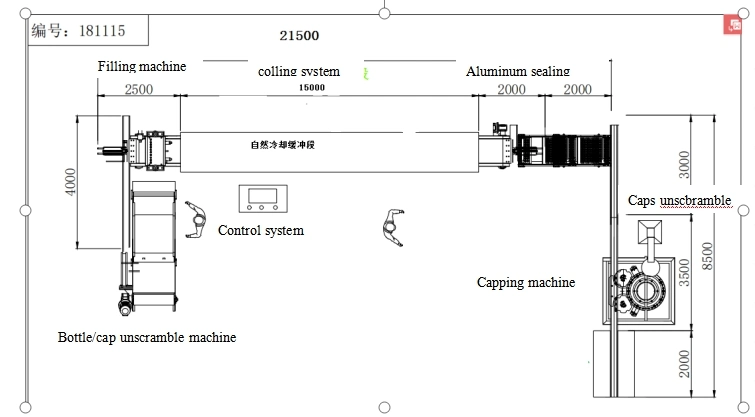

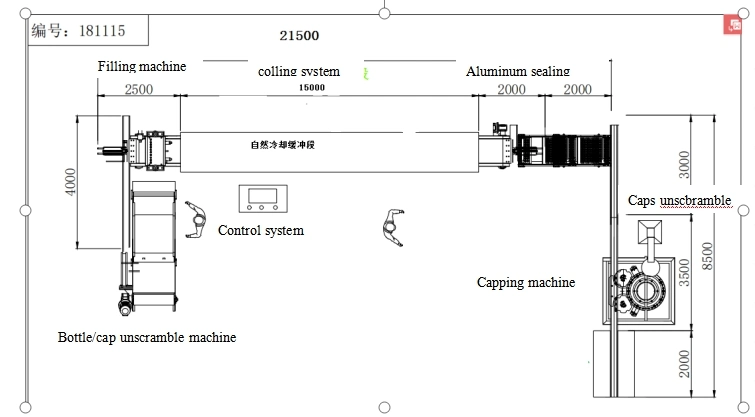

Manual pour empty bottles into bottle unscrambling machine -- > sorts bottle -- > hot filling -- > nature cooling ( or industrial refrigerator cooling ) --> aluminum foil sealing -- > capping machine ( or crimping cap ) -- > ink-jet printer -- > finish

Introduction:

This Vaseline production line is our unique developed patent base on foreign and mainland technology with our years experience, for high efficient produce jar, can container was, vaseline, petroleum jelly and others products.

Feature:

Process steps:

Manual pour empty bottles into bottle unscrambling machine -- > sorts bottle -- > hot filling -- > nature cooling ( or industrial refrigerator cooling ) --> aluminum foil sealing -- > capping machine ( or crimping cap ) -- > ink-jet printer -- > finish

Introduction:

This Vaseline production line is our unique developed patent base on foreign and mainland technology with our years experience, for high efficient produce jar, can container was, vaseline, petroleum jelly and others products.

Feature:

- This auto Vaseline ointment filling machine with cooling is especially designed by our company for liquid or paste hot filling cooling of various jars & bottles, like shoes polisher filling, Vaseline filling, balm filling, deodorant filling, car wax filling or Simone filling etc.

2) This production line consists of bottle-unscrambling, bottle hot filling, cooling system, cap-feeding, cap-pressing/closing & bottle-collecting. (labeling or date ink jetting if needed)

3) PLC system to control, easy to operate & adjust.

4) Linear bottle in-out, can be easily adjusted to suit bottles or containers of different sizes & specification.

5) Can be customized based on different customers' production requirements & capacity.

- Compact structure, stable performance.

High speed bottle unscrambling machine:

This part of machine is custom made base on client's bottle. It can be link to linear production line. Made of stainless steel, high level automatic, with auto alarm system when the hopper is lack of bottles or caps.

Feature:

- Operation system : using traditional button, it is simple and safety.

- Speeding : can be adjusted according to the production need.

- Maintenance : meet GMP standard, easy disassemble for cleaning.

| Voltage | 220v 50hz | Air pressure | 0.2-0.3mpa |

| Power | 0.12kw | Cap/bottle max size | Custom made |

| Speed | 10000BPH | Size | 650*650*2000mm |

| Weight | 250kg | Material | SUS304 |

Filling machine :

This automatic heating filling machine was developed by our team import foreign advanced technology on the base of hot heating production market requirement. The whole machine is made of stainless steel 304. Designed with various heads and specification accordance to customer's demands. It is wildly used for chemical, pharmaceutical, food, cosmetic and other industries production.

Feature:

- By adopting unique heated filling system, filling precision is high. The whole structure is easy disassemble for cleaning and sterilization.

- Touch liquid material part with temperature protection function.

- Filling nozzles unique patent design for suitable for different high bottle.

- For different viscous density liquid filling, high filling accuracy.

- Imported brand PLC control system, frequency inverter for adjusting sped.

- Simple operation, not only can independent adjusting 1 filling nozzle, but also can adjusting all filling nozzles at one time.

- The filling nozzles with anti-leaking function design.

- Meet GMP standard.

Main parameter:

| Filling nozzles | Custom made | Air compressor | 0.4~0.6MPa |

| Fillign scope | Custom made | voltage | 220V 50/60Hz |

| Filling speed | Custom made | powder | 0.75kw |

| Filling accuracy | ≤±1% | noise | ≤50dB |

| Size | Depend on product | Weight | Need to custom designed |

Electric component:

| PLC | Taiwan Delta | Pneumatic components | Taiwan AirTAC |

| Touch screen | Taiwan Weinview | Conveying motor | French Schneider / Germany Siemens |

| servo motor | Taiwan Delta | Photoelectricity | Japan Keyence |

| Frequency converter | Taiwan Delta / French Schneider | cylinder | Taiwan AirTAC |

| Low-voltage electricals | French Schneider |

Aluminum foil sealing machine:

- This machine is custom made non standard device. Mainly consist of aluminum and stainless steel. Then manipulator will take bottle onto the aluminum mold when photo electronic device detect product. Rolling foil sealing, special structure designed.

- Aluminum foil speed controlled by timely.

- Sealing knife drive by cylinder.

- With frequency inverter control speed.

Main parameter:

| Voltage | Three phase, four wire | Sealing heads | Custom made |

| Air pressure | 6-8KG | Foil material | aluminum |

| capacity | Custom made | Suitable bottle/can | Custom made |

| Size | 2500*1000*1600 | power | 50HZ 380V 9KW |

Auto capping machine:

- This device consist of cap lifter, high speed cap sorter, and continuously rotary screwing/crimping cap set.

- Frequency inverter adjusting speed. Running stable without noise.

- Automatic counting and displaying function on screen.

- Cylinder control capping torque.

- High speed design which can meet most of production speed line demand.

Parameter:

| Suitable cap | Custom made | Air pressure | 10.4MPa-0.6MPa |

| capacity | Meet to the pre production line | Air consumption | 20m³/h |

| quality | ≥99% | Voltage/ power | 50HZ 380V 9KW |

| Size | 3500*1200*2000 | voltage | 3 phrase 4 wire |

Electric component:

| PLC | Taiwan Delta | Pneumatic components | Taiwan AirTAC |

| Touch screen | Taiwan Weinview | Conveying motor | French Schneider / Germany Siemens |

| servo motor | Taiwan Delta | Photoelectricity | Japan Keyence |

| Frequency converter | Taiwan Delta / French Schneider | cylinder | Taiwan AirTAC |

| Low-voltage electricals | French Schneider |